Hemt Fabrication Process

Process Flow For Fabrication Of Protected And Passivated Aln Gan Download Scientific Diagram

Electronics Free Full Text A Comprehensive Review Of Recent Progress On Gan High Electron Mobility Transistors Devices Fabrication And Reliability Html

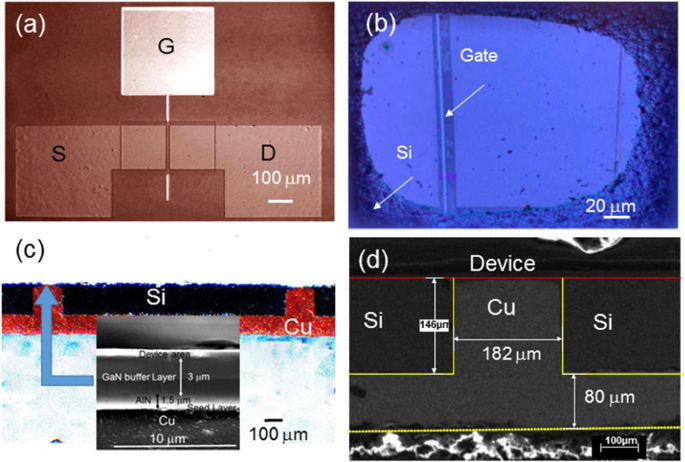

Novel Junction Level Cooling In Pulsed Gan Devices

Thermal Management Of Gan On Si High Electron Mobility Transistor By Copper Filled Micro Trench Structure Scientific Reports

Efficiency Improved By Monolithic Integration Of Hemt With Vertical Structure Leds And Mg Doping On Dry Etched Gan Journal Of Materials Chemistry C Rsc Publishing

Stars Library Ucf Edu Cgi Viewcontent Cgi Article 7690 Context Etd

GaN HEMT devices are particularly significant in power electronics applications.

Hemt fabrication process. The most common materials used aluminium gallium arsenide (AlGaAs) and gallium arsenide (GaAs). Power HEMT using field plate Submitted By :- Vivek Kumar Surana. APEX Plastics is dedicated to manufacturing high quality blow-molded plastic products, providing timely deliveries and creating an atmosphere of continuous improvements where all employees strive to keep both internal and external customers satisfied.

IPS is a full-service solutions provider and equipment distributions firm representing a complete line of process equipment, pumps, water/waste treatment systems, mixers, heat exchangers, valves, motors and drives as well as other related. C Fabrication Process of AlGaN/GaN HEMT 101 D De-embedding 105 Bibliography 113 Acknowledgement 121 iv. System Plus Consulting unveils the GSB from GaN Systems, the latest device driving 100V and optimized for AC-DC converters and high-frequency, high-efficiency power conversion.

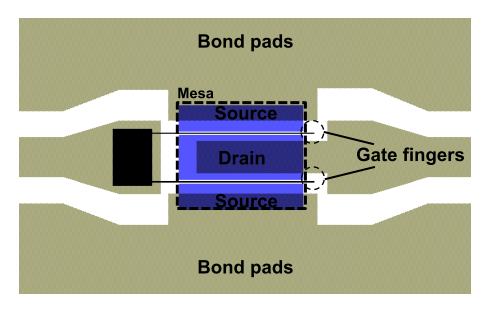

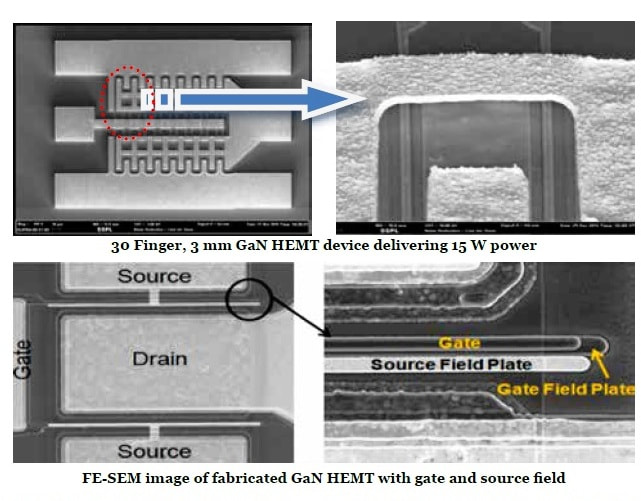

Round HEMTtechnology, which greatly simplifies the microelectronic fabrication process compared to traditional open fingers HEMT, was employed. We can also provide device manufacturing and material analysis. Initially, HEMT devices are fabricated in serpentine geometries using our standard process shown in Fig.

MESFET HEMT Oscillator –. A backside via etch process for both circular and slot vias through the SiC substrate has been successfully developed and qualified for the fabrication of GaN-on-SiC HEMT MMIC devices. Wafer in Process Lecture 2 Fabrication Processes.

Foundry and material analysis services NTT-AT also provides process services (including MEMS device prototyping, and etching services) and material analysis services. The key element within a HEMT is the specialised PN junction that it uses. Devices incorporating more indium generally show better high-frequency performance, while in recent years, gallium nitride HEMT.

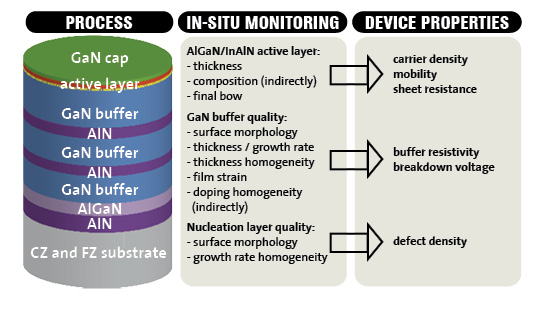

Large Signal Performance • W-Band Device Performance (94 GHz) • Ka-Band Device Performance (30 GHz) IV. Manufacturing Process Flow - GaN HEMT Process Flow and Fabrication Units - Resistor Process Flow and Fabrication Units - MOSFET Process Flow and Fabrication Units - Package Process Flow 6. Studies on Fabrication and Reliability of GaN High-Resistivity-Cap-Layer HEMT Abstract:.

Process flow for fabrication of protected and passivated AlN/GaN MOS-HEMTs using the gate wrap-around technique. The sample is then mounted to glass slides using epoxy with. Passive Die Fabrication Unit;.

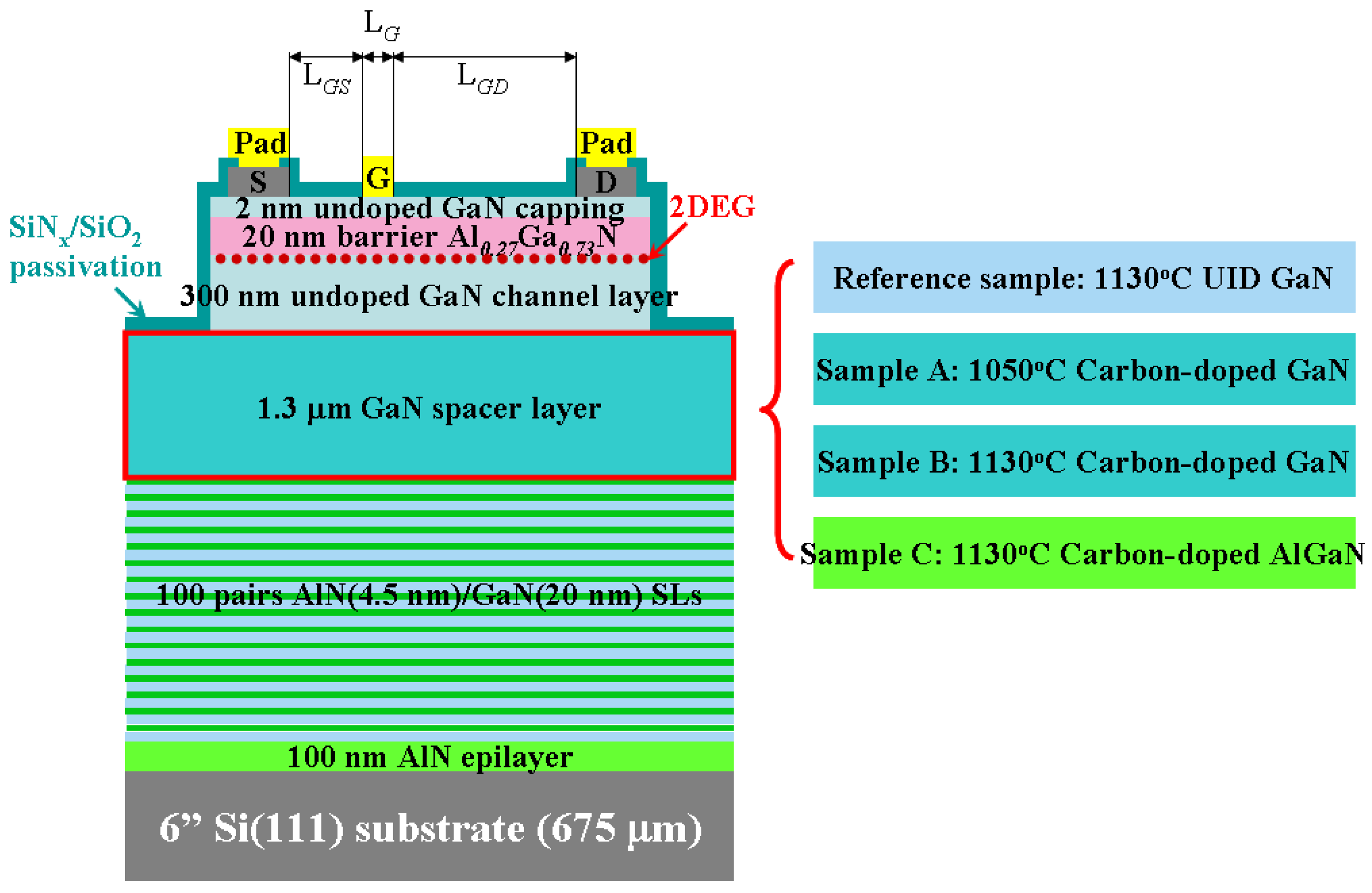

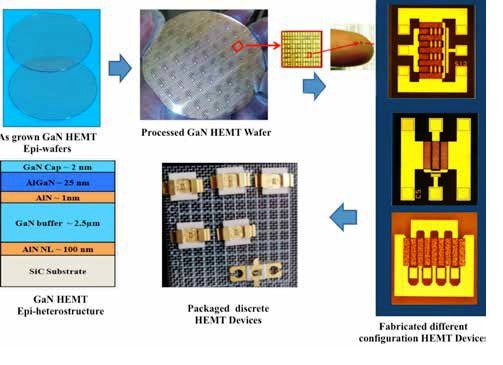

On the second part of the dissertation, Aluminum gallium nitride/gallium nitride high electron mobility transistors (AlGaN/GaN HEMTs) were fabricated. Summary of the Cost Analysis;. 140nm GaN 0.42m Al0.10Ga0.90N 70 nm Grad up to Al0.10 Ganm 70 AlN (HT) 0.90N.

What is claimed is:. This is only about 1micron thick. Click here to download a leaflet of InAlN/GaN HEMT (PDF:385KB).

Wet EtchWet Etch Selectively remove material Chemical ProcessChemical Process Chemical Bath Patterned Photo-resist Wafer in Process Lecture 2 Fabrication Processes. Summary of the Cost Analysis;. HEMT Die Front-End Process and Fabrication Unit;.

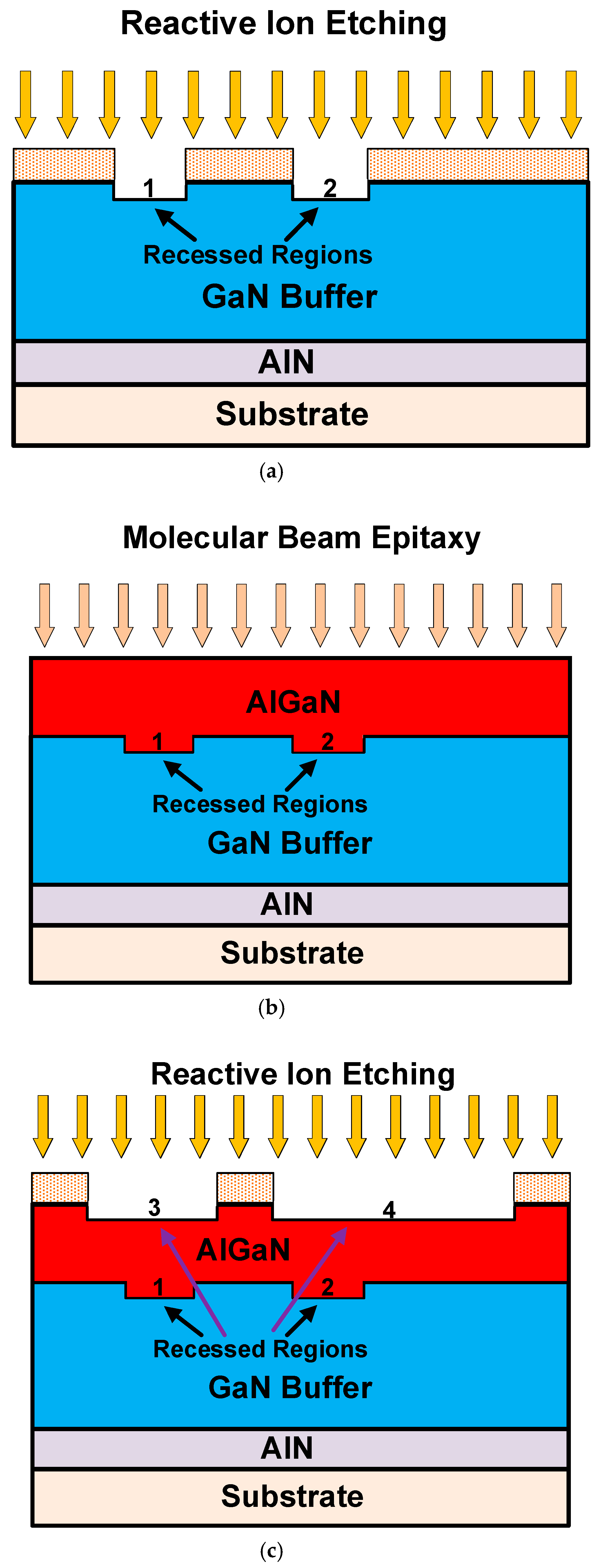

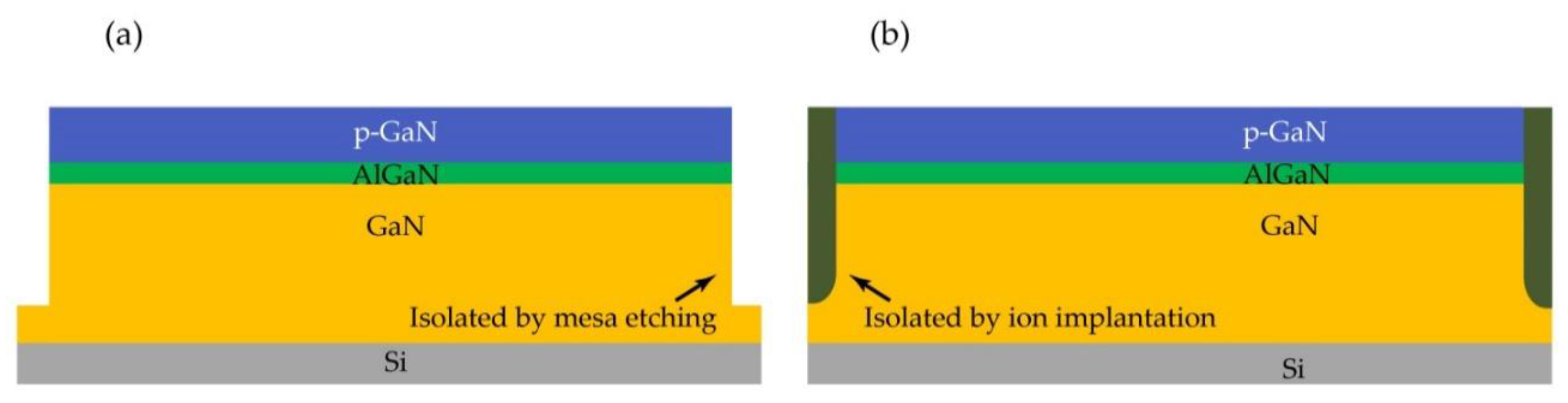

Giorgia Longobardi (Cambridge - UK). In general, a Cl 2 based mixture gas is used to etch GaN.15,16) In addition, to reduce damage from the etching, the inductively coupled plasma reactive ion etching (ICP-RIE) technique is com-monly applied.17) For electrical isolation of the HEMT fabrication process in this study, ICP dry etching with. GaN Transistor Fabrication Process.

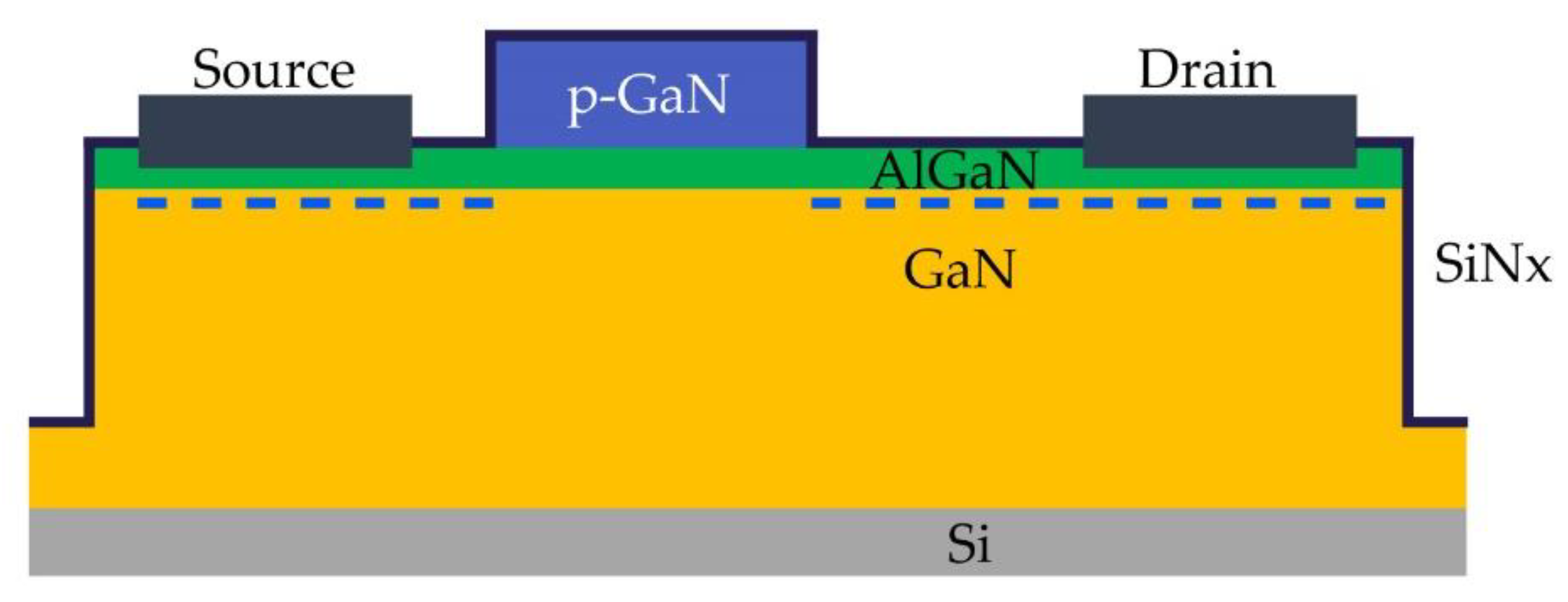

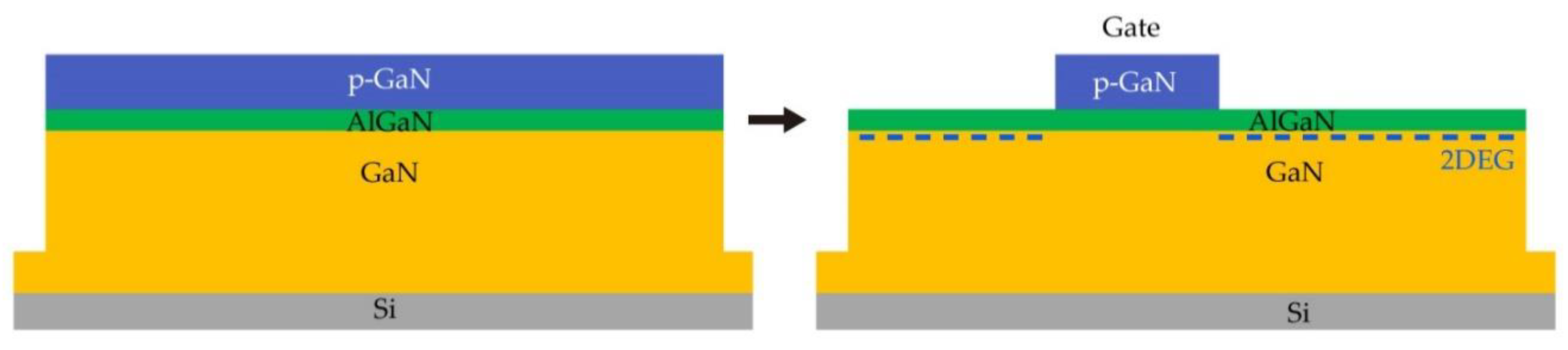

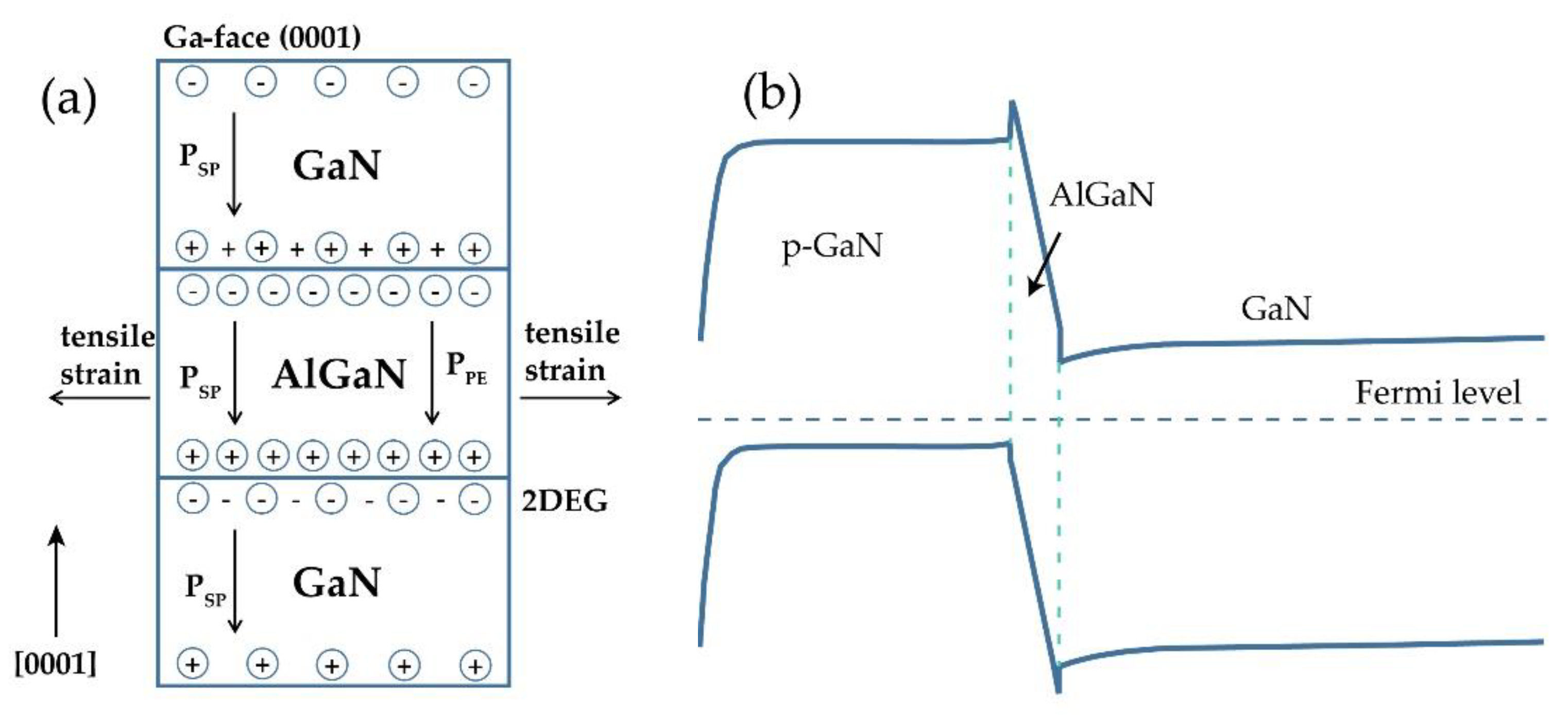

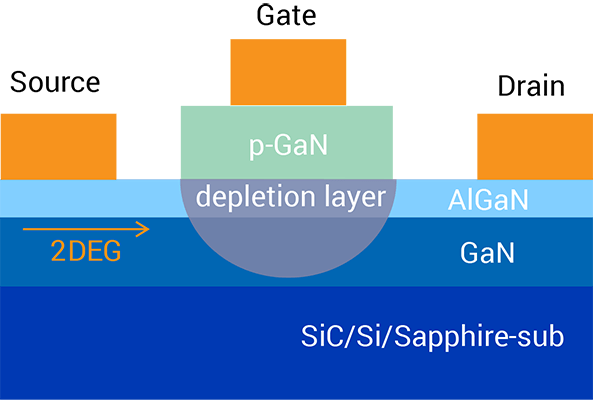

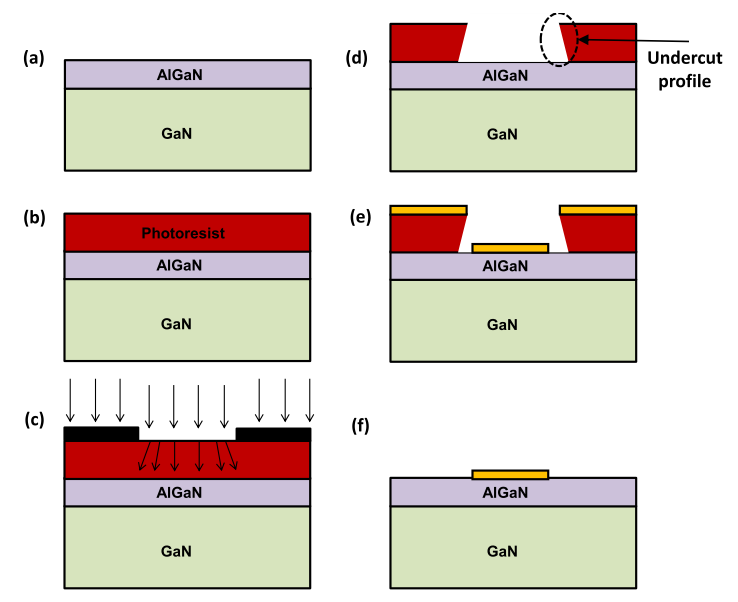

In this paper, we systematically investigate the effect of hydrogen plasma treatment radio frequency (RF) power, treatment time, and rapid thermal annealing (RTA) on the performance of high-resistivity-cap-layer high-electron-mobility-transistor (HRCL-HEMT). In this section, we will focus on some of the key process technologies for the fabrication of p-GaN E-mode AlGaN/GaN HEMTs, discuss some of the challenges and. This video is a TCAD simulation tutorial for power GaN HEMT (High Electron Mobility Transistor).

Dry etch ÆInP etch stop layer removal:. 3 SiC STEP 1 SiNx passivation 300nm SiNx. GaAs pHEMT technology is suitable for cellular backhaul, linear digital radios, V-band, E-band and W-band radar applications, among others.

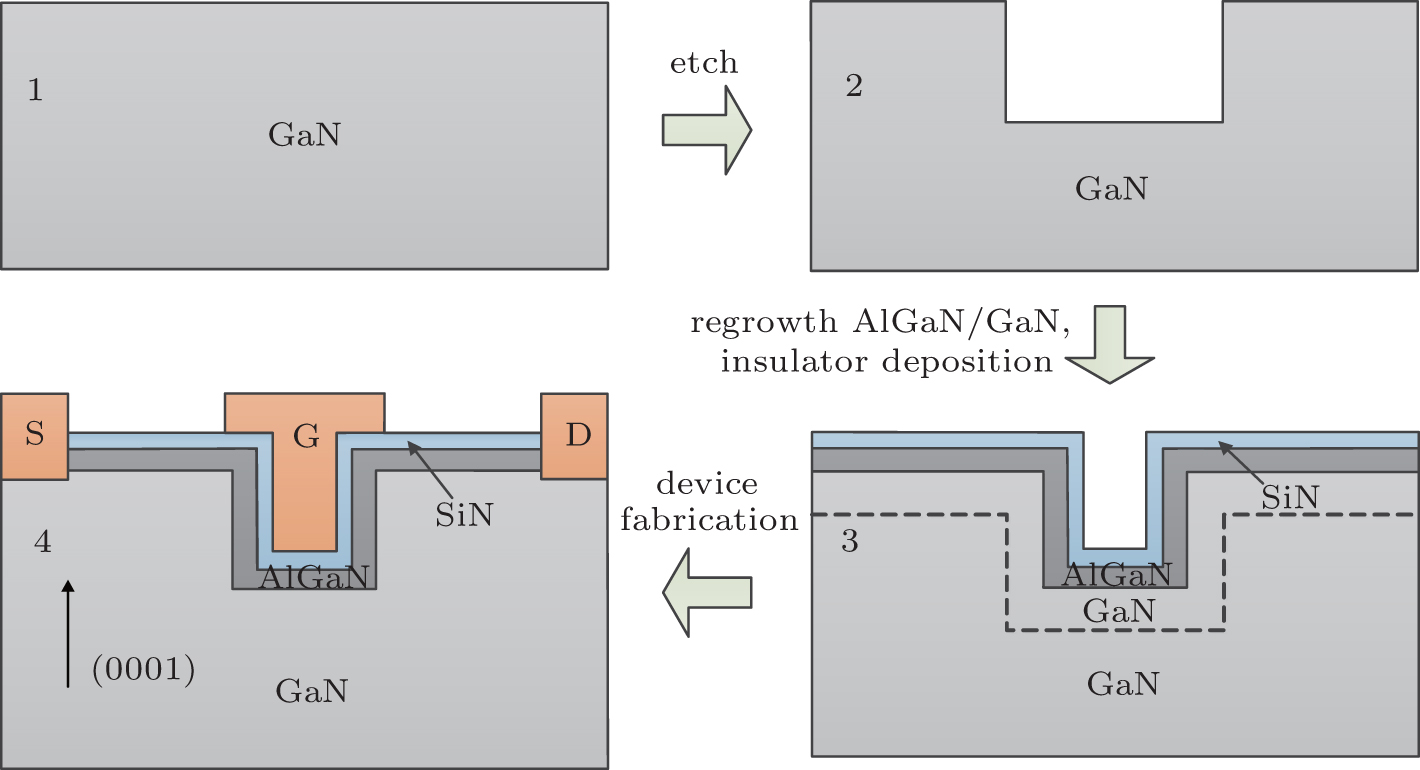

A schematic of our fabrication process is sh own in Fig. One of the challenges in GaN power device fabrication is to achieve a “normally off” operation. A voltage source coupled to the pair of Schottky metal conductive contacts to generate an electric field sufficiently high to alter.

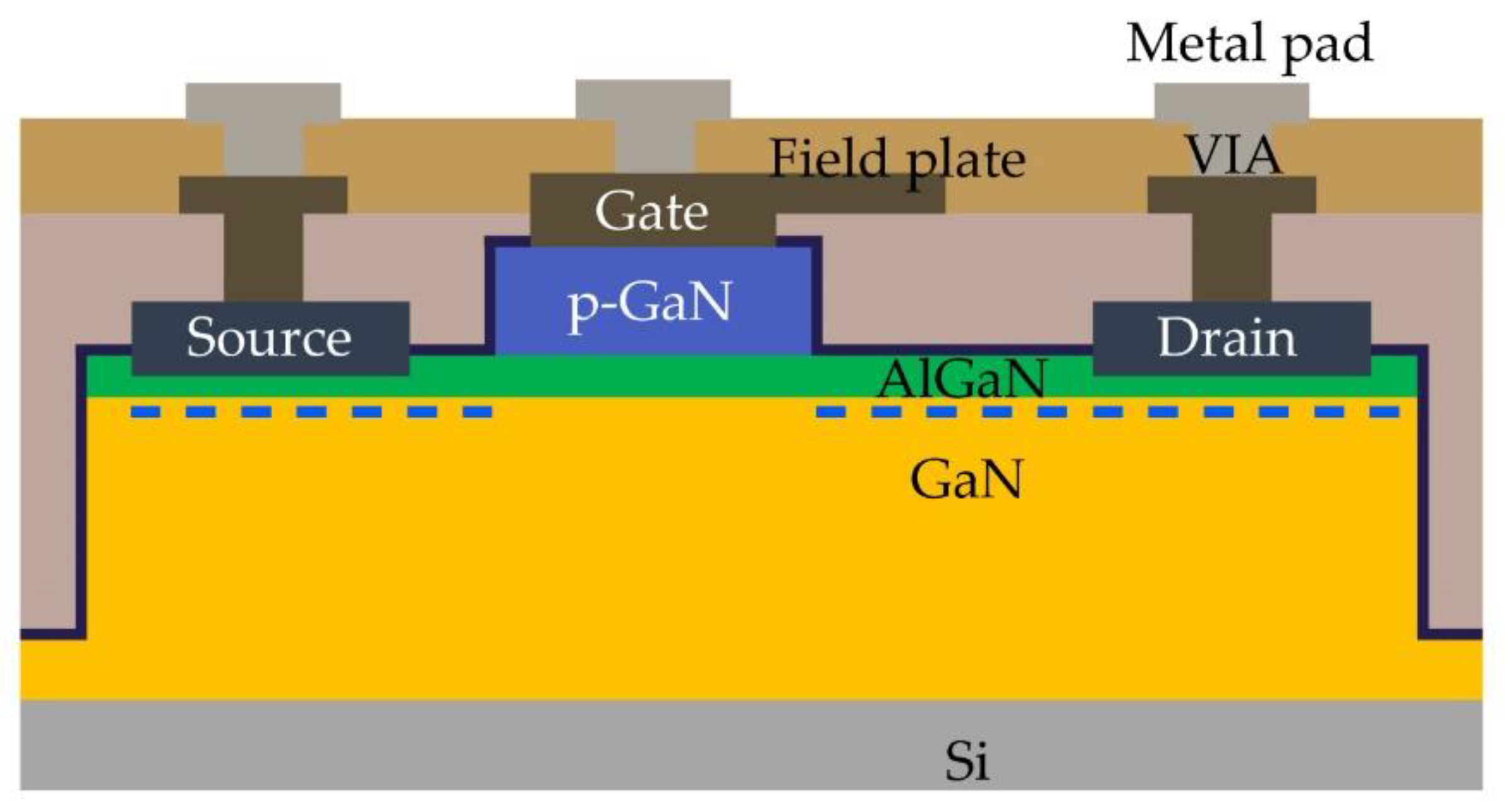

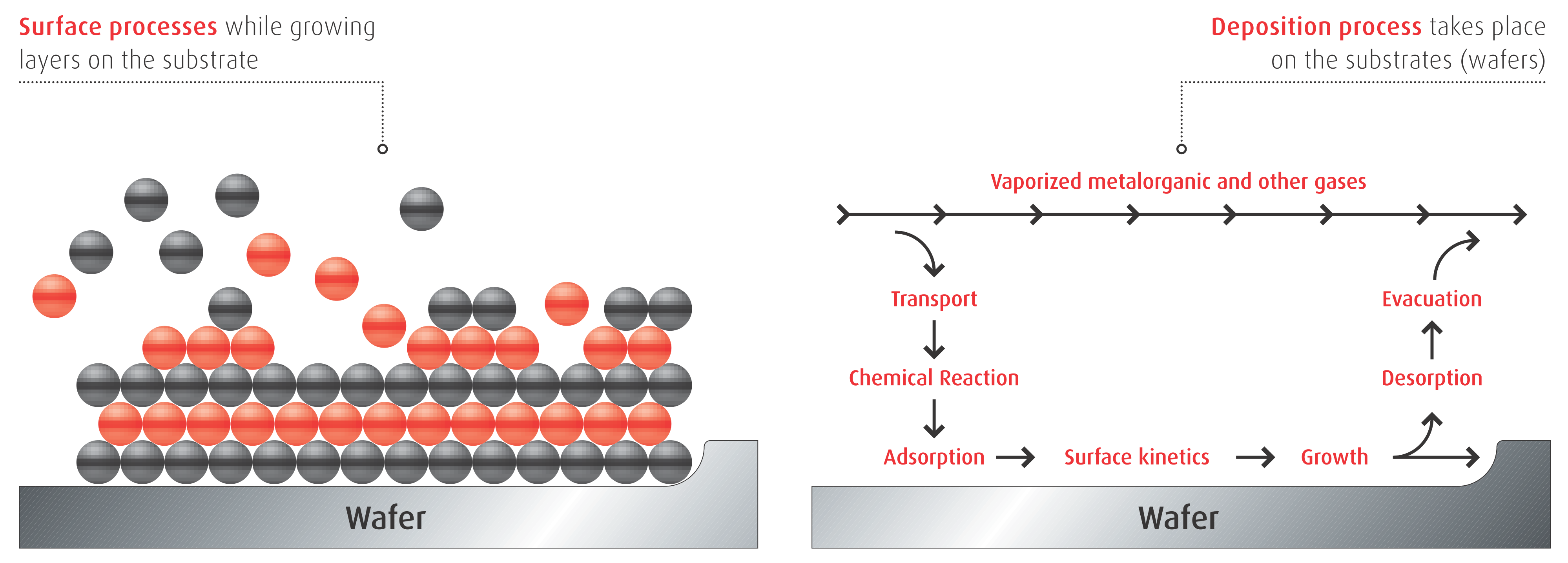

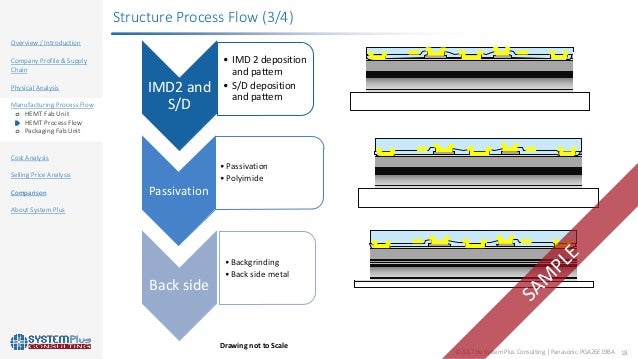

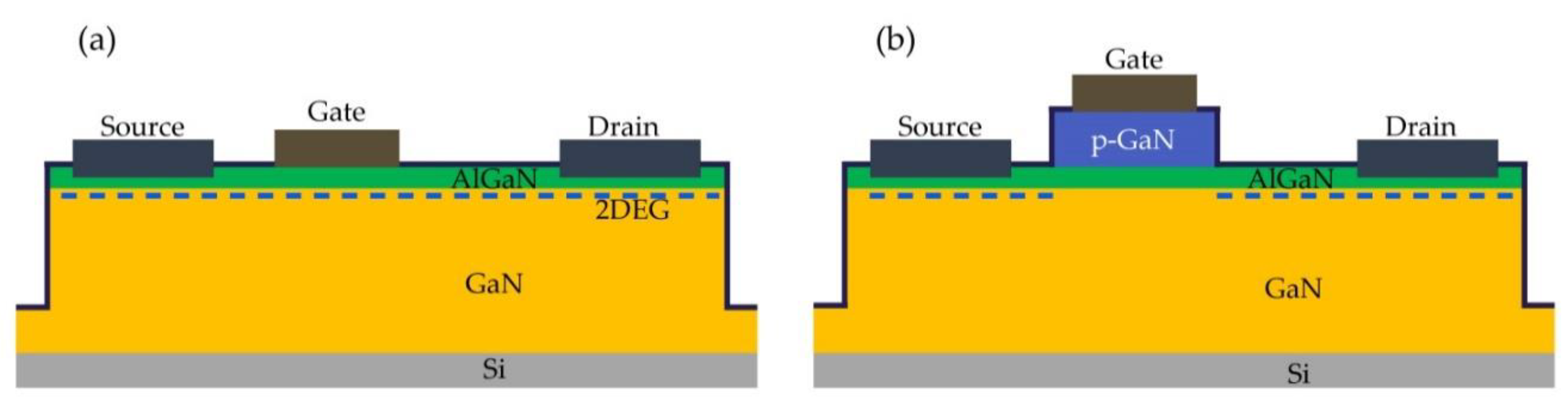

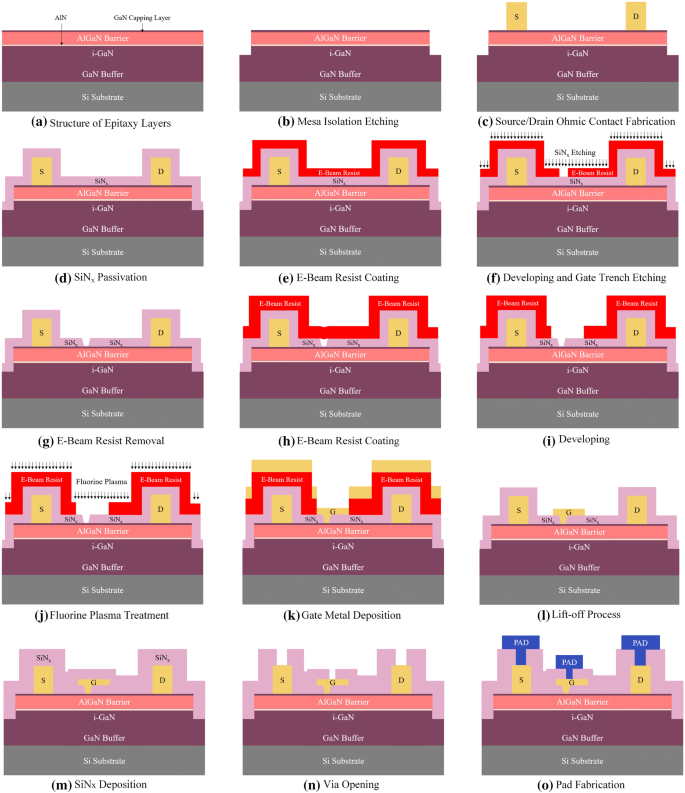

The process modules for the GaN HEMT device fabrication include device isolation, p-GaN gate formation , contacts for source and drain , contact for gate , surface passivation and so forth. The gate-first fabrication process flow began with plasma. Based on Cree GaN high electron mobility transistors (HEMTs), the new MMIC is built on a SiC substrate using a 0.25μm gate length fabrication process.

HEMT Die Front-End Process;. Chemical vapor deposition (PECVD) just before the HEMT fabrication process because the N-polar GaN surface is easily etched with the alkaline developer in the photolithography process.19) The gate was 10µm long. Manufacturing Process Flow o HEMT Fab Unit o HEMT Process Flow o ICs Fab Unit o ICs Process Flow o Component Packaging Cost Analysis Selling Price Analysis Comparison Related Reports About System Plus Description of the Wafer Fabrication Unit –IC Die 1 oIn our calculation, we simulate a production unit using 150mm wafers.

The process modules for the GaN HEMT device fabrication include device isolation, p-GaN gate formation, contacts for source and drain, contact for gate, surface passivation and so forth. HEMT Wwafer front-end cost and front-end cost per process step;. A key process in this study is dry etching.

The HEMT structure consisted of a nm Al 0.25Ga 0.75N barrier layer on a 150nm GaN channel/buffer. Structure to be used. HEMT structure & fabrication.

Technical parameters Deosited by ICPCVD SiH4/N2/Ar=2.8/9/90sccm Power 0W Pressure 35mTorr. Alcatel Speeder 100 SiO 2. While AlGaN/GaN High Electron Mobility Transistors (HEMT) devices are generally “normally on” and require a circuit to turn off the devices, a normally-off operation is preferred for safety concerns.

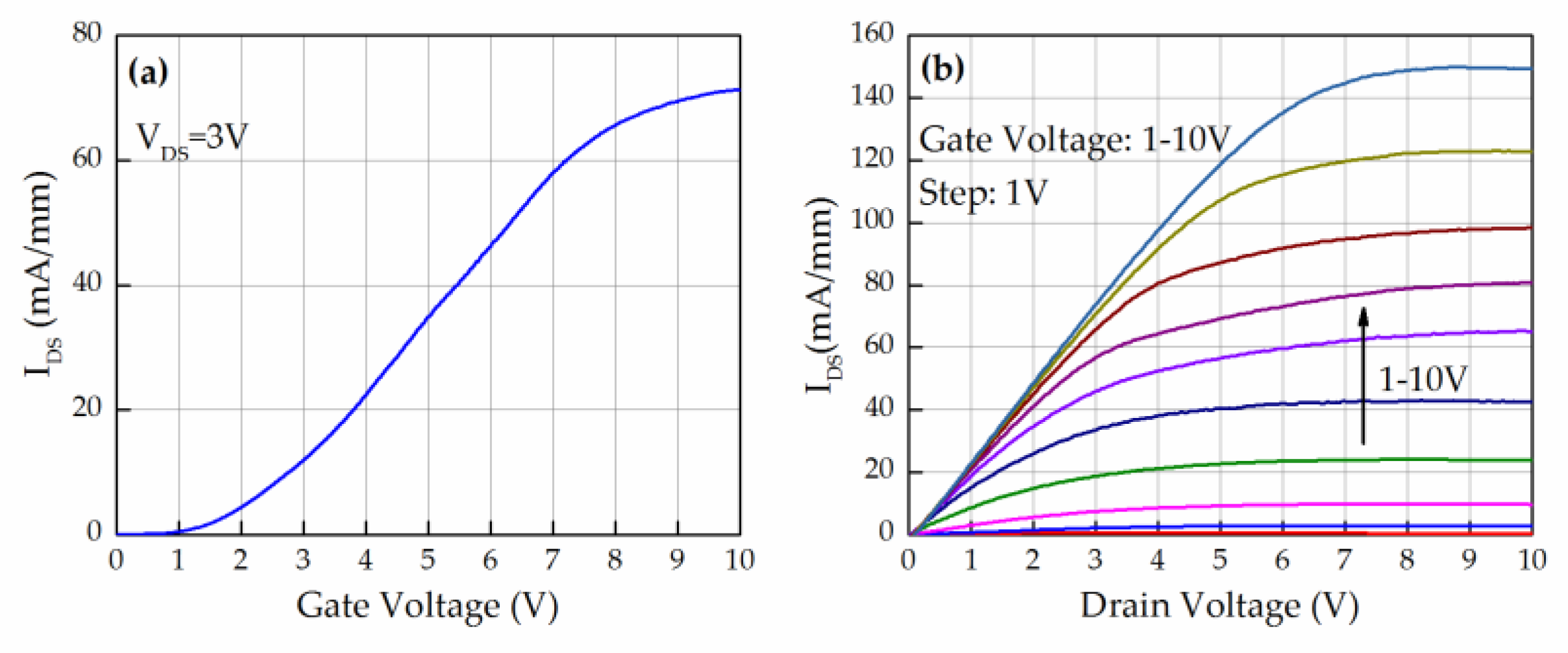

Welcome to APEX Plastics - Blow Molding Manufacturing Experts. The Alcatel "Speeder 100SiO 2" is an ICP Etching system which is configured for etch silicon using either the patented BOSCH Deep Silicon Etch Process or a Cryogenic etch process that are typically used in MEMS (Micro-ElectroMechanical Systems), microfluidics, and silicon masters for soft lithography stamps.The system is setup to process 4" wafers and uses etch masks. The work started with establishing the main features of AlInN/GaN heterostructure in a HEMT configuration through optimizing the device fabrication and investigation of the DC characteristics of planar HEMTs.

Each single step of this process was optimized in order to improve device performance. HEMT Die Fabrication Unit;. Thus, an alternative approach is required in order to obtain improvement in the gate leakage.

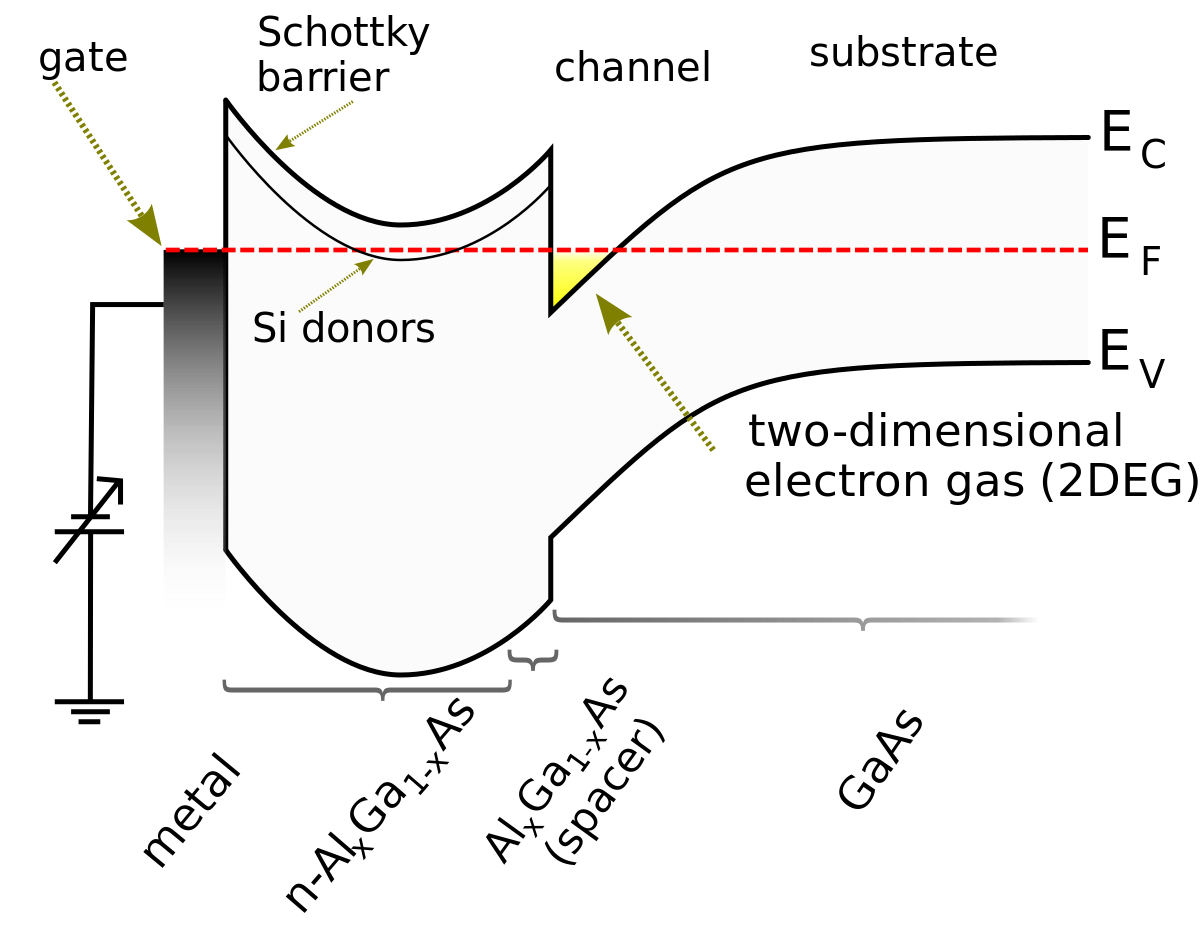

The two-dimensional electron gas (2DEG) channel was formed near the GaN/AlGaN interface with 1.0x1013/cm2 carrier density, 1.5x10 3cm2/V-s mobility, and 450Ω/square sheet resistance. Fabrication Steps(D-mode HEMT) 1WaferCleaning 2Mask#1:MesaEtching 3RIEMesaEtching 4Mask#2:S/DContacts 5OhmicContactDeposition 6Mask#3:GateLithography 7SchottkyGateDeposition 8GrowthofPassivationLayer 9Mask#4:ContactHoleOpening 10Mask#5:Fieldplateandmetallization SimplifiedGaN-on-SapphireHEMTProcessFlow(GaN-on-siliconissimilar):. Properties to realize AlInN/GaN HEMTs.

Fabrication HEMT has a fully equipped fabrication shop, capable to carry out fabrication of various types of process equipments like pressure vessel, heat exchangers, separator, columns etc. An optically controlled Schottky diode-based transistor comprising:. The whole process flow to fabricate a HEMT mainly includes five steps, namely mesa isolation, ohmic contact formation, gate formation, pad and.

An Inductively Coupled Plasma (ICP) etch is then done to expose the Si substrate (Fig. Processing includes (a) sample cleaning and deoxidation, (b) 2 nm Al deposition, (c) etching Ohmic regions and thermal oxidation of Al, (d) Ohmic metallisation and annealing, and (e) gate metallisation and device measurements. A pair of co-planar Schottky metal conductive contacts coupled to the III-nitride semiconductor layer;.

A series of process improvements have been implemented to etch through the SiC substrate and clean the via sidewall/via bottom effectively. In a today´s world of semiconductor devices silicon transistors dominate, while GaAs-based high mobility transistors (HEMTs) and heterojunction bipolar transistors (HBTs). 12 nm Al0.30Ga0.70N 10 nm Al2 Ga0.70 N:Si nm Al0.30 Ga0.70N 0.30 1 nm AlN.

GaAs pHEMT process of UMS foundry. Herein, we have demonstrated highly sensitive. In this paper, we present a method for removing a high electron mobility transistor (HEMT) silicon substrate using mechanical grinding and deep silicon etching technology and successfully transferred the epitaxial wafer to a PET substrate to achieve the flexible normally-off HEMT.

In this study, we report a fabrication process of a normally-off GaN MIS-HEMT with a gate leakage current as low as on the order of 10 −11 A/mm by exploiting a hydrofluoric (HF) acid pre-treatment prior to gate formation. A detailed explanation of how to edit the process input file. In addition, the feed pads to the gate fingers are optically printed by I-line exposure.

FABRICATION, MODELING AND CHARACTERIZATION OF GaN HEMTs, AND DESIGN. The N-Polar GaN Deep Recess HEMT • Enabling Features of the Device Structure • Fabrication Process for Self-Aligned Gate III. A III-nitride semiconductor layer having an active region;.

The high electron mobility transistor (HEMT)-based biosensors are highly competitive in the ultimate application of portable and point-of-care testing. A commonly used material combination is GaAs with AlGaAs, though there is wide variation, dependent on the application of the device. CNA CN.2A CNA CNA CN A CN A CN A CN A CN A CN A CN A CN A CN A Authority CN China Prior art keywords hemt dorsal pore gaas gallium arsenide plating Prior art date Application number CN.2A.

After that, a very thin layer between 30 and 60 Angstroms of intrinsic Aluminium Gallium Arsenide is set down on top of this layer. GaN Systems wants to compete with EPC, the market leader, in the low-voltage HEMT market. IC Die Front-End Processes and Fabrication Units;.

Yield Explanations and Hypotheses;. The manufacture of an HEMT as follows procedure, first an intrinsic layer of Gallium Arsenide is set down on the semi-insulating Gallium Arsenide layer. Wet etch Æn+InGaAs/InAlAs multi-layer cap removal • 2ndstep:.

In the 100mm InP HEMT process, fabrication of the MIM capacitor is started at the beginning of the MMIC process prior to the completion of the HEMT device using a double-layer nitride process. For isolating neighbor-ing FETs, all epitaxial layers in the region between FETs were etched by Cl 2-based inductively coupled plasma. Passive Die Front-End Process;.

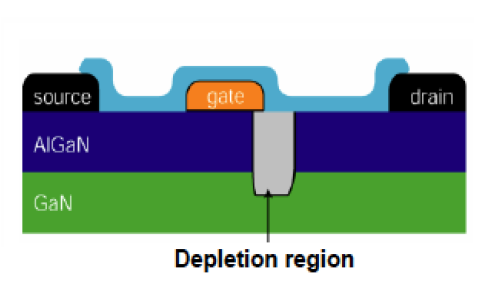

A high-electron-mobility transistor, also known as heterostructure FET or modulation-doped FET, is a field-effect transistor incorporating a junction between two materials with different band gaps as the channel instead of a doped region. Exchange program supported by the Erasmus+ agreement between the University of Napoli federico II a. We have expertise in fabrication of various types of structural works, water tanks, fixed type water tanks, diesel tank, frack tanks, etc.

We introduced two-stage balanced PA. Currently the so-called "embedded gate process" where the gate is processed into an insulator trench is commonly used for AlGaN/GaN HEMT gate fabrication. Critical Process for Nano-HEMT Buffer Channel Insulator Cap ZEP Buffer Channel Insulator ZEP Ar-based plasma & ALET InP InP Wet etching Two-step recess for HEMT fabrication • 1ststep:.

HEMT Die Front-End Process and Fabrication Unit;. This chapter describes a few key process steps to fabricate GaN high-electron-mobility transistors (HEMTs) for power electronics applications. IC Die Front-End Processes and Fabrication Units;.

HEMT Die HEMT wafer front-end cost and front-end cost per process step. Summary of the Cost Analysis;. Lecture given by Dr.

It is known as a hetero-junction and consists of a junction that uses different materials either side of the junction. GAN HIGH ELECTRON MOBILITY TRANSISTORS 8 2.1 GAN MATERIAL PROPERTIES8 2.2 PRINCIPLE OF GAN HEMT S. Yield Explanations and Hypotheses;.

MBE • Molecular Beam EpitaxyMolecular Beam Epitaxy. Gallium Arsenide (GaAs) HEMT Matches Technologies & Applications Northrop Grumman offers a range of GaAs pHEMT processes for matching technologies with applications. • Ar-based RIE (Conventional).

In order to verify the compatibility of the process with device fabrication, electron mobility and sheet density were measured using Van der Pauw structures at room temperature on a metamorphic InGaAs/InAlAs HEMT structure before and after deposition and etching of a 300 nm silicon nitride film. Die probe test, thinning and.

Gan Power Devices The Hemt Youtube

Color Online Cross Sectional Schematic Of Algan Gan Hemt Fabrication Download Scientific Diagram

Boron Nitride Releases Gan Transistors From Self Heating Degradation

A Fabrication Process Of The Algan Gan Hemt Structure B Download Scientific Diagram

State Of The Art On Gate Insulation And Surface Passivation For Gan Based Power Hemts Sciencedirect

Gan Sic Based High Electron Mobility Transistors For Integrated Microwave And Power Circuits

Algan Gan Hemts Versus Inaln Gan Hemts Fabricated By150 Nm Y Gate Process Semantic Scholar

Blog Archives Full Afterburner

Moscap And Hemt Process Flows A Moscap Process Flow N Gan Substrate Download Scientific Diagram

Aln Gan Based Mos Hemt Technology Processing And Device Results

Efficiency Improved By Monolithic Integration Of Hemt With Vertical Structure Leds And Mg Doping On Dry Etched Gan Journal Of Materials Chemistry C Rsc Publishing

Normally Off Hemt Device With Field Plates Power Microelectronics Device And Process Technologies

Electronics Free Full Text A Comprehensive Review Of Recent Progress On Gan High Electron Mobility Transistors Devices Fabrication And Reliability Html

An Aunps Functionalized Algan Gan High Electron Mobility Transistor Sensor For Ultrasensitive Detection Of Tnt Rsc Advances Rsc Publishing

A Fabrication Process Of The Algan Gan Hemt Structure B Download Scientific Diagram

Cghv1j025d 25 W 18 0 Ghz Gan Hemt Die Wolfspeed

A Schematic Cross Section And Dimensions Of The Hemts B Device Download Scientific Diagram

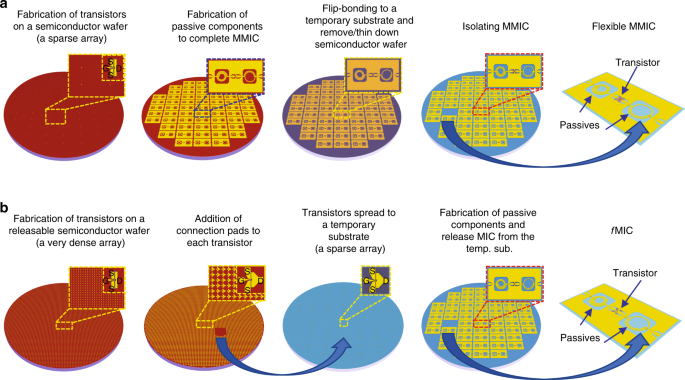

Heterogeneously Integrated Flexible Microwave Amplifiers On A Cellulose Nanofibril Substrate Nature Communications

Substrate Transfer Technique Using H Bn For Gan Based High Power Transistors Ntt Technical Review

Review Of Technology For Normally Off Hemts With P Gan Gate Sciencedirect

2

Schematics Showing The Process Flow Of E D Mode Hemts A Ohmic Download Scientific Diagram

Scholarcommons Sc Edu Cgi Viewcontent Cgi Article 4657 Context Etd

A Fabrication Process Of The Algan Gan Hemt Structure B Download Scientific Diagram

World S First Multi Cell Gan Hemt Bonded Directly To Diamond Substrate

Q Tbn 3aand9gcsrmh6hxn2xcbtvnht2hdks4ohqsytrioqtpw Usqp Cau

Schematic Views Of The Process Flow For Micro Trench Fabrication In Download Scientific Diagram

Gan Based Gas Sensors Department Of Electrical And Electronics Engineering

Color Online Illustration Of The Planar Fabrication Process Of E Mode Download Scientific Diagram

Electronics Free Full Text A Comprehensive Review Of Recent Progress On Gan High Electron Mobility Transistors Devices Fabrication And Reliability Html

650v D Mode Gan Hemts Produced On 0mm Gan On Si Wafers With Cmos Compatible Process News

Electronics Free Full Text A Comprehensive Review Of Recent Progress On Gan High Electron Mobility Transistors Devices Fabrication And Reliability Html

Transfer Printing And Self Aligned Etching For E Mode Gan Transistors

An Effective Hydroxylation Route For A Highly Sensitive Glucose Sensor Using Aptes Gox Functionalized Algan Gan High Electron Mobility Transistor Rsc Advances Rsc Publishing

Review Of Technology For Normally Off Hemts With P Gan Gate Sciencedirect

Http Citeseerx Ist Psu Edu Viewdoc Download Doi 10 1 1 1012 8152 Rep Rep1 Type Pdf

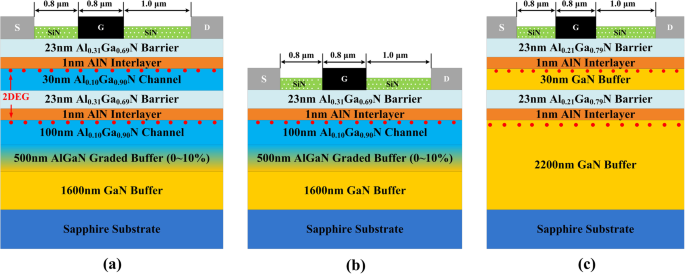

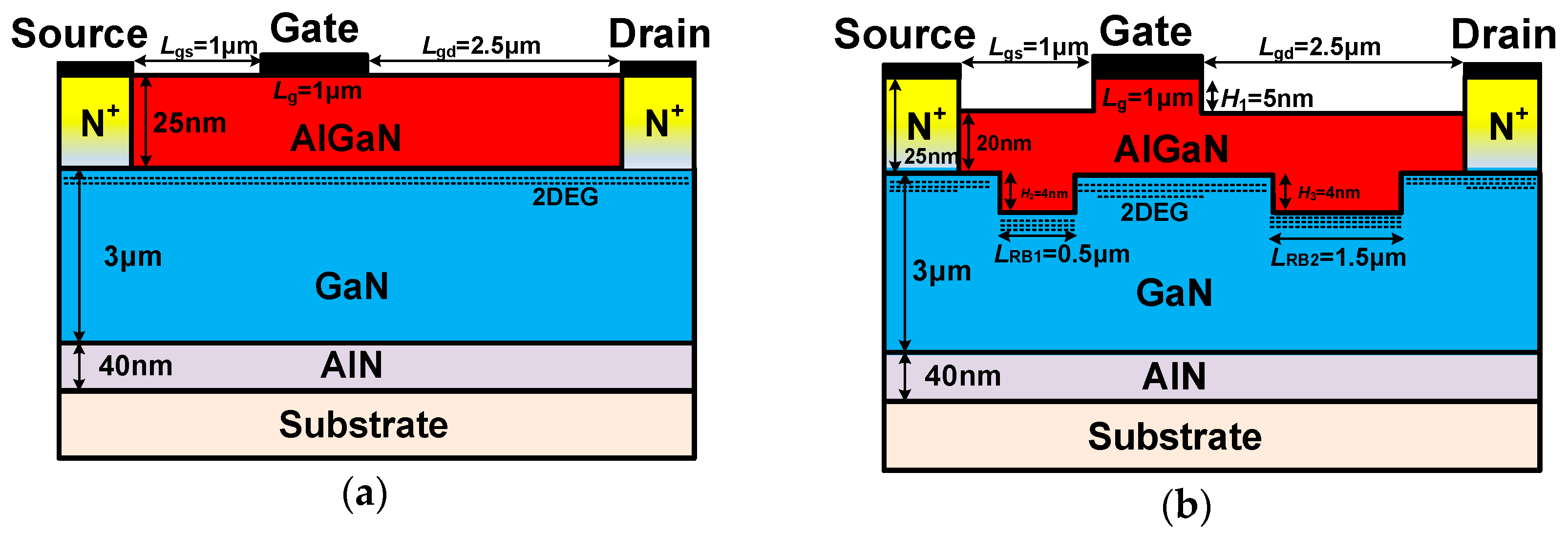

Micromachines Free Full Text Novel High Energy Efficiency Algan Gan Hemt With High Gate And Multi Recessed Buffer Html

Device With Process Simplification And Ar Pretreatment Of Al2o3 Before F Plasma Treatment To Create Deeper Electron Traps For High Temperature Operation Power Microelectronics Device And Process Technologies

High Rf Performance Enhancement Mode Al2o3 Algan Gan Mis Hemts Fabricated With High Temperature Gate Recess Technique Semantic Scholar

Cree Cghv1j070d 70w Dc 18 Ghz Gan Hemt Die Cree Inc

2

High Electron Mobility Transistor Wikipedia

Figure 1 From In0 17al0 n Aln Gan Triple T Shape Fin Hemts With Gm 646 Ms Mm Ion 1 03 A Mm Ioff 1 13 µa Mm Ss Mv Dec And Dibl 28 Mv V At Vd 0 5 V Semantic Scholar

Moscap And Hemt Process Flows A Moscap Process Flow N Gan Substrate Download Scientific Diagram

High Performance Algan Double Channel Hemts With Improved Drain Current Density And High Breakdown Voltage Nanoscale Research Letters Full Text

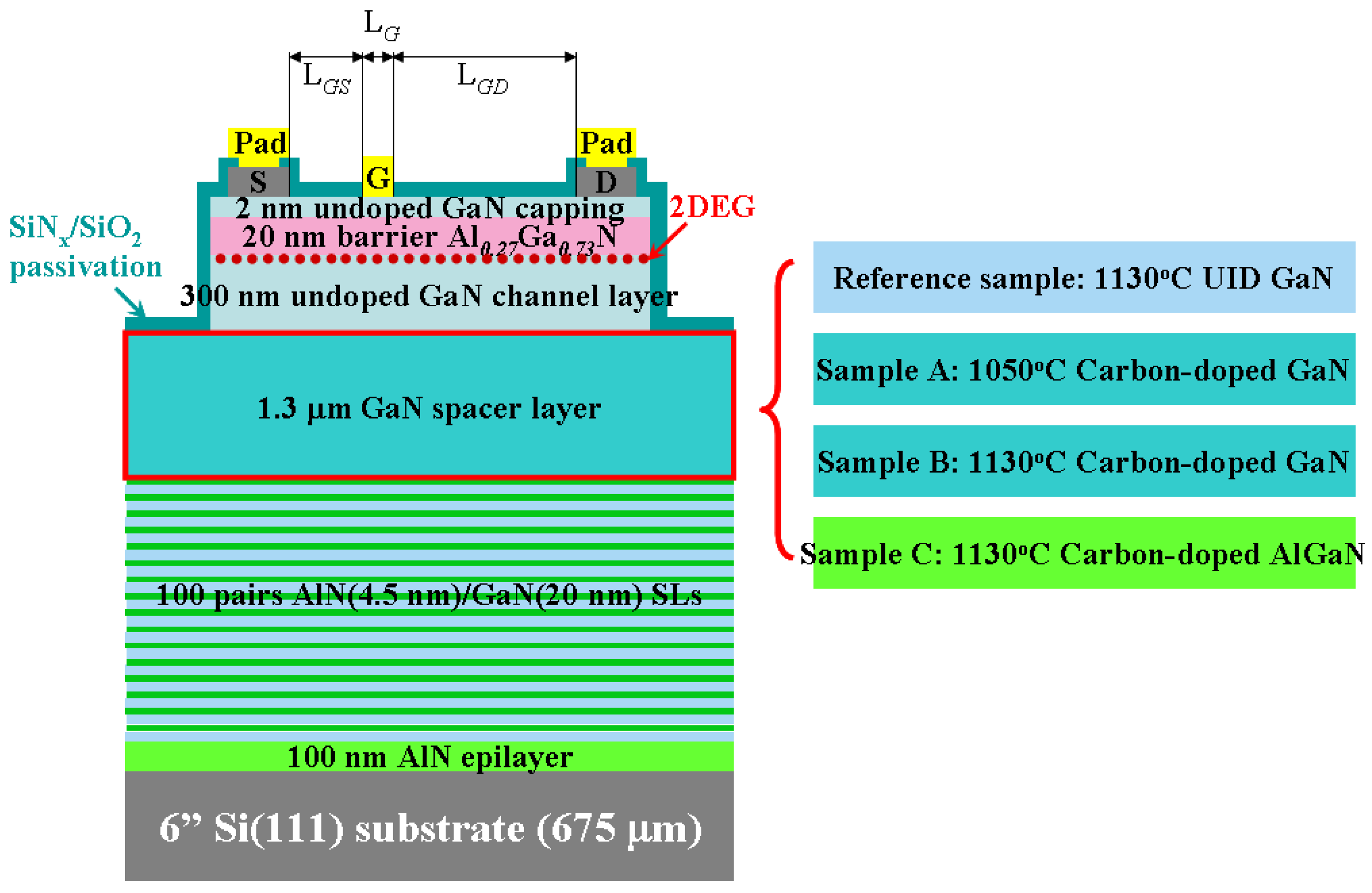

Electronics Free Full Text An Investigation Of Carbon Doping Induced Current Collapse In Gan On Si High Electron Mobility Transistors Html

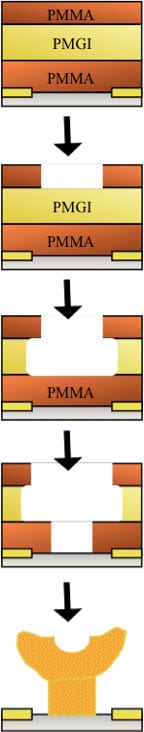

Fabrication Of 22 Nm T Gates For Hemt Applications Sciencedirect

Process Flow For Fabrication Of Protected And Passivated Aln Gan Download Scientific Diagram

Wolfspeed Cghvgan On Silicon Hemt Chip And Module Fabrication Process Overview

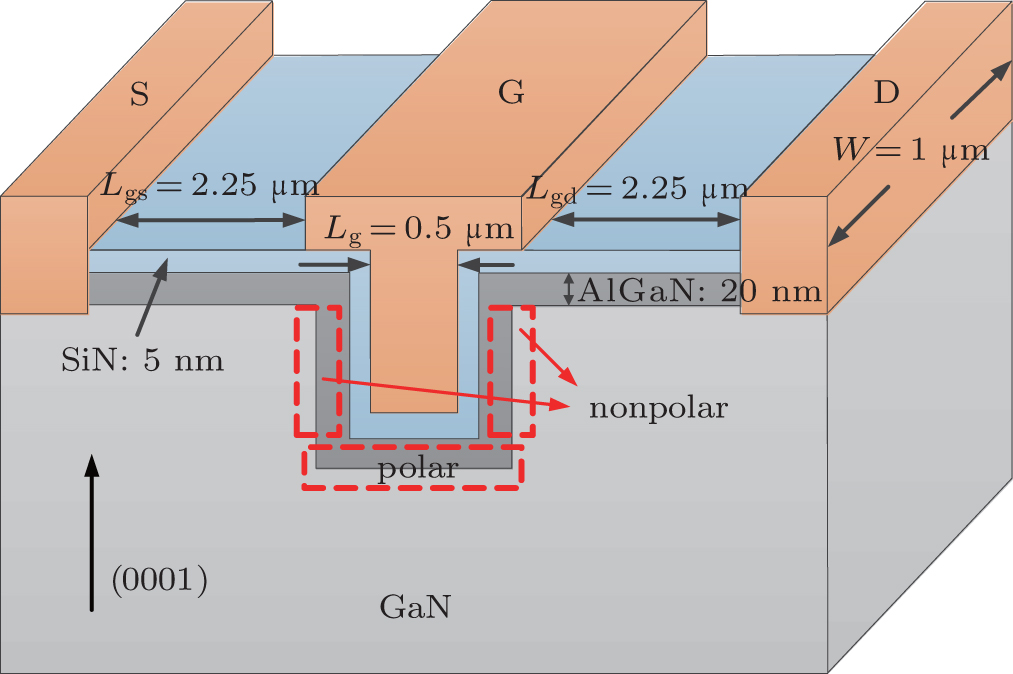

Groove Type Channel Enhancement Mode Algan Gan Mis Hemt With Combined Polar And Nonpolar Algan Gan Heterostructures

Fabrication Process For The Proposed Algan Gan Vertical Hemts With Sio Download Scientific Diagram

Figure 1 From Advantage Of Tin Schottky Gate Over Conventional Ni For Improved Electrical Characteristics In Algan Gan Hemt Semantic Scholar

High Electron Mobility Transistor Wikipedia

A Sandwich Structured Algan Gan Hemt With Broad Transconductance And High Breakdown Voltage Journal Of Materials Chemistry C Rsc Publishing Doi 10 1039 C9tcg

Electronics Free Full Text A Comprehensive Review Of Recent Progress On Gan High Electron Mobility Transistors Devices Fabrication And Reliability Html

Schematic Representations Of The Fabrication Processes For A Sample Download Scientific Diagram

Mitsubishi Electric Develops World S First Multi Cell Gan Hemt Bonded Directly To Diamond Substrate 19 09 10 Microwave Journal

Schematic Illustration Of The Fabrication Process Of The Algan Gan Download Scientific Diagram

Figure 3 From 1 6kv 2 9 Mw Cm2 Normally Off P Gan Hemt Device Semantic Scholar

Figure 3 From 0 1 M M Inp Hemt Mmic Fabrication On 100 Mm Wafers For Low Cost High Performance Millimeter Wave Applications Semantic Scholar

Electronics Free Full Text A Comprehensive Review Of Recent Progress On Gan High Electron Mobility Transistors Devices Fabrication And Reliability Html

Gan Sic Based High Electron Mobility Transistors For Integrated Microwave And Power Circuits

Laytec Power And Rf Electronics

Panasonic 600 V Gan Hemt Pga26e19ba 17 Teardown Reverse Costing Rep

Sensors Free Full Text Algan Gan High Electron Mobility Transistor Based Biosensor For The Detection Of C Reactive Protein Html

Low Noise High Power Gan Hemt Technology For Manualzz

Gan Hemt Power Device Tcad Simulation Youtube

High Electron Mobility Transistor Hemt Construction And Applications

Small Signal Model Parameters Analysis Of Gan And Gaas Based Hemts Over Temperature For Microwave Applications Sciencedirect

Algan Gan Hemt Fabrication And Challenges Handbook For Iii V High Electron Mobility Transistor Technologies Taylor Francis Group

Scholarworks Rit Edu Cgi Viewcontent Cgi Article 1568 Context Ritamec

Stress Induced By Intrinsically Strained Silicon Nitride Passivation Films Of Algan Gan Hemts Using Victory Process 2d

Algan Gan Etch For Gan Power Device Fabrication Samco Inc

Electronics Free Full Text A Comprehensive Review Of Recent Progress On Gan High Electron Mobility Transistors Devices Fabrication And Reliability Html

Gan Sic Based High Electron Mobility Transistors For Integrated Microwave And Power Circuits

Schematics Showing The Process Flow Of The Ln Zno Algan Gan Hemts A Download Scientific Diagram

Groove Type Channel Enhancement Mode Algan Gan Mis Hemt With Combined Polar And Nonpolar Algan Gan Heterostructures

T Gate Fabrication Using Pmgi And Pmma Kayaku Advanced Materials

Effects Of Gate Shaping And Consequent Process Changes On Algan Gan Hemt Reliability Topic Of Research Paper In Materials Engineering Download Scholarly Article Pdf And Read For Free On Cyberleninka Open Science

Monolithic Integration Of Nitride Semiconductor Hemts And Leds

Transfer Printing And Self Aligned Etching For E Mode Gan Transistors

New Fabrication Process To Manufacture Rf Mems And Hemt On Gan Si Substrate Semantic Scholar

Figure 1 From Aln Surface Passivation Of Gan Based High Electron Mobility Transistors By Plasma Enhanced Atomic Layer Deposition Semantic Scholar

Micromachines Free Full Text Novel High Energy Efficiency Algan Gan Hemt With High Gate And Multi Recessed Buffer Html

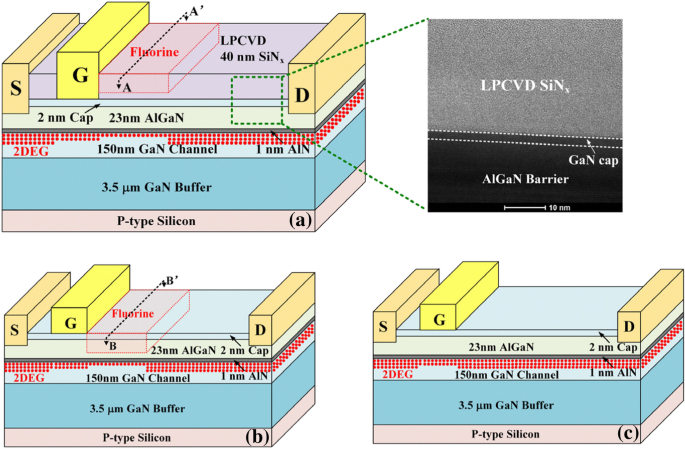

High Breakdown Voltage And Low Dynamic On Resistance Algan Gan Hemt With Fluorine Ion Implantation In Sin X Passivation Layer Nanoscale Research Letters Full Text

Designing Algan Gan Hemts For W Band Microwaves Rf

Gan Sic Based High Electron Mobility Transistors For Integrated Microwave And Power Circuits

Molecular Gated Algan Gan High Electron Mobility Transistor For Ph Detection Analyst Rsc Publishing

Low Leakage Gan Hemts With Sub 100 Nm T Shape Gates Fabricated By A Low Damage Etching Process Springerlink

Tel Archives Ouvertes Fr Tel Document

Blog Archives Full Afterburner

Iopscience Iop Org Article 10 1149 2 jss Pdf

Figure 10 From A Gaas Soi Hemt Fabricated By Fluidic Self Assembly And Its Application To An Rf Switch Semantic Scholar

Transphorm Gan On Silicon Hemt Tph36ps 16 Teardown Reverse Costin